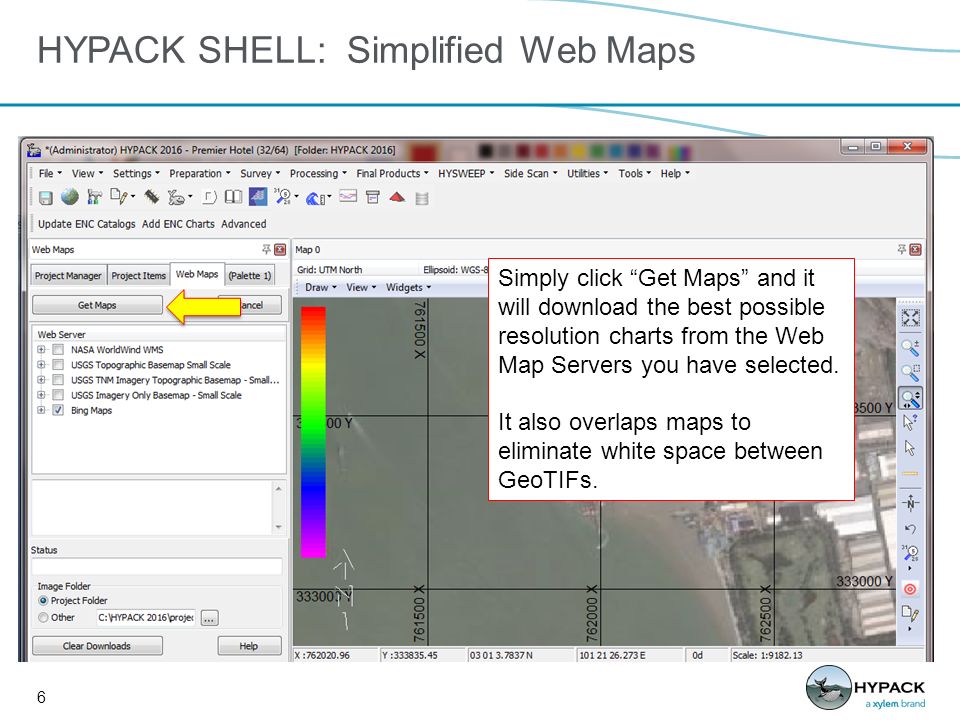

In tight quarters around structures, the Sigsbee served as a manned platform that could run at shallower depths and was more manoeuvrable than the larger vessel ,” said DEA Marine Services’ senior vice president and director Jon Dasler, PE, PLS, CH. In open waters, the Sigsbee would run unmanned, collaboratively following and thereby widening the swath of the manned vessel in the shallow waters of Galveston Bay. “Having the flexibility to operate a survey vessel manned or unmanned offered tremendous versatility in the conduct of a tough survey. To meet the unique needs of the NOAA project requirements, DEA chose to integrate its command station aboard a second, larger vessel that would serve as the mothercraft for the mission with the Sigsbee collaboratively following. With the Sea Machines technology integrated aboard Sigsbee, DEA was able to start executing autonomous missions in reduced crew or unmanned configurations from a nearby support boat. More Data Collection, Less Risk and Effort DEA network specialists also installed a remote access capability aboard all vessels to enable DEA lead hydrographers to control PCs and instrumentation from anywhere with internet access. Working with Hypack, the unmanned vessel coverage was displayed with the manned vessel coverage, and lines started and stopped in sync with the Hypack software.

Using hypack remote view over internet Pc#

(Photo credit: DEA)ĭEA also installed a wireless network to enable crew aboard the manned vessel to command and control the survey PC and instrumentation aboard the Sigsbee. Although not integrated for this survey, the system missions can consider and interpret data from radar, AIS, GPS, ENCs and more to help operators execute highly efficient, predictable and safe routes.Ī view from the bridge of the mothership: an on-board operator sets the flanking offset distance of the daughter craft Sigsbee (shown) using the Sea Machines SM300 as it autonomously surveys West Galveston Bay. The SM300 comes equipped with an on-board, ruggedized computer powered by TALOS technology (‘the brain’) that allows operators to plan, track and record missions using Electronic Navigation Chart (ENC) information. This SM300 system allowed the survey vessel Sigsbee to operate as a daughter craft and provided DEA with new capabilities that increased the vessel’s value. For DEA, Sea Machines’ innovative technology increased the operational productivity of the vessels involved.įollowing the installation of the SM300 aboard an existing DEA survey vessel in November 2020, DEA completed sea trials and began operations in Galveston Bay, the area designated by the US Coast Guard for unmanned vessel operations for the project. The Texas survey, a prototype mission for unmanned operations, posed numerous challenges to marine surveyors, including a large geographic area, variable shallows, numerous obstructions and unpredictable sea conditions.

Approximately 15% of the total survey mileage was acquired autonomously. (DEA), of Vancouver, Wash., has invested in and utilized Sea Machines Robotics’ autonomous command and remote helm control system aboard DEA survey vessels to more efficiently fulfil a National Oceanic and Atmospheric Administration (NOAA) contract to survey more than 60 square nautical miles of the West Galveston Bay. DEA Marine Services, a division of David Evans and Associates, Inc.

0 kommentar(er)

0 kommentar(er)